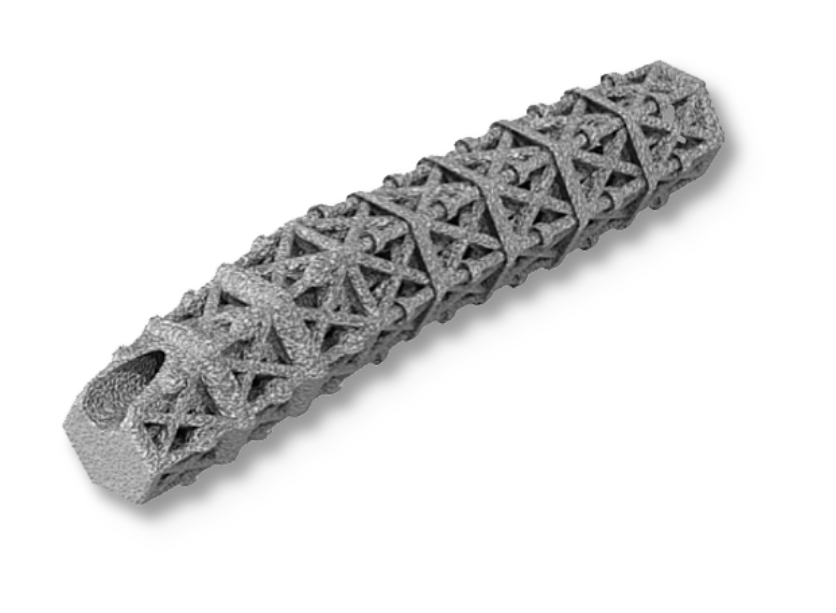

An orthopedic implant company focused on developing innovative implants with an Advanced Structural Design that utilizes its proprietary Truss Implant Technology™. This technology leverages a mechanobiological mechanism inherent to its truss design that may stimulate an osteogenic response to facilitate fusion

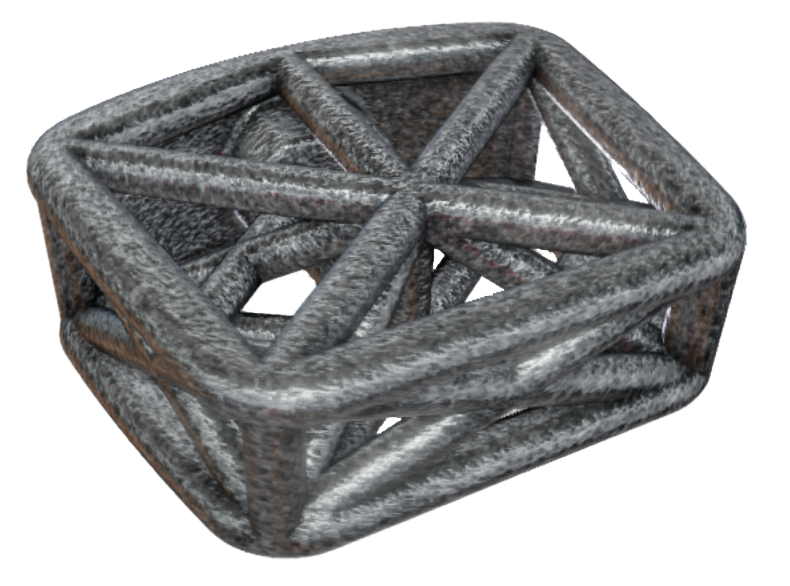

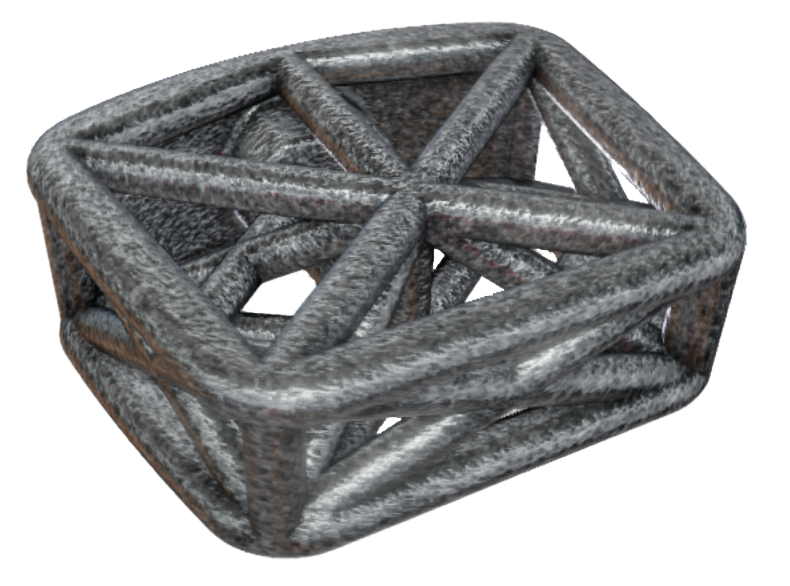

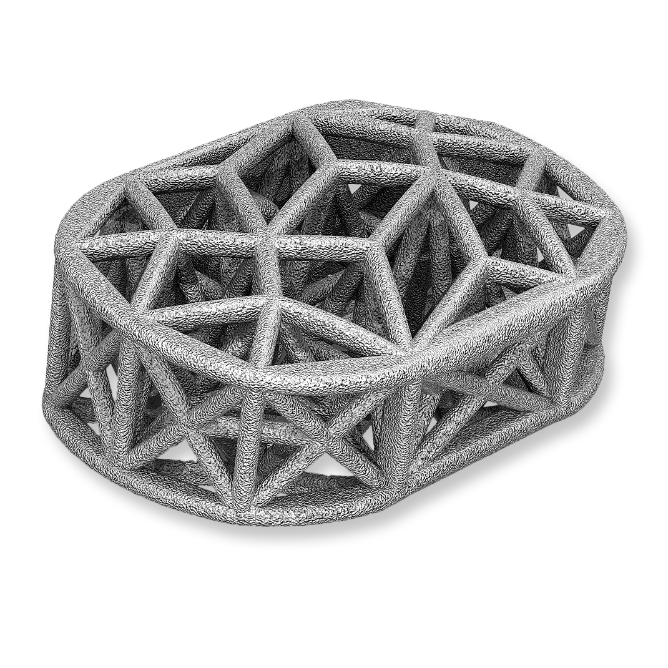

Thirty years of research in topological dimension theory led to the discovery of a novel geometry, that can be used as a building block to create high-strength, lightweight web structures. The company leveraged this breakthrough to develop proprietary truss implant platform which was the first 510(k) cleared implant manufactured with 3D printing technology.

Actively developing truss implant designs for tumor, trauma, and patient-specific applications.

The emerging field of science at the interface of biology and engineering that focuses on how physical forces and changes in the mechanical properties of cells and tissues contribute to development, cell differentiation, proliferation, and healing.

Distribution of load through the implant struts delivers strain to adjacent cellular material which stimulates a mechanobiologic response.

Allows for greater graft volume and bone growth throughout the entire construct.

Provides maximum strength with a minimal amount of material, which limits imaging artifacts.

Spans from the macro to nano scale. These surface features have been shown to stimulate increased gene expression of certain osteogenic markers when compared to other interbody surfaces and materials.

Provides a Snowshoe Interface that distributes load across the endplate minimizing point loading and reducing the risk of subsidence.

Truss Implant Technology provides a synergistic relationship between the hierarchical surface roughness and the truss architecture to create a cascade of osteogenic activity that supports the fusion process over time.

hierarchical surface roughness has been shown to provide an environment that allows for bone growth and fusion

Under normal physiologic loading conditions, the truss implant distributes strain through the struts to adjacent cellular material, amplifying the osteogenic activity initiated by the implant surface technology.

Additionally, in vitro testing has also shown that stem cells cultured in an osteogenic medium demonstrate increased expression of certain osteogenic markers on titanium hierarchical surface roughness compared to smooth titanium and smooth PEEK

Cervical and lumbar spine solutions

Osteotomy and hammertoe solutions

Cure Health Solutions

8 The Green # 16321

Dover, DE 19901